Shorter projects and experiments

TBW process

10 Oct 2019

Building the hardware for Turn-by-Wire, and preparing to transport it to the UIST 2019 Demo Reception.

Always Be Knolling

Always Be Knolling

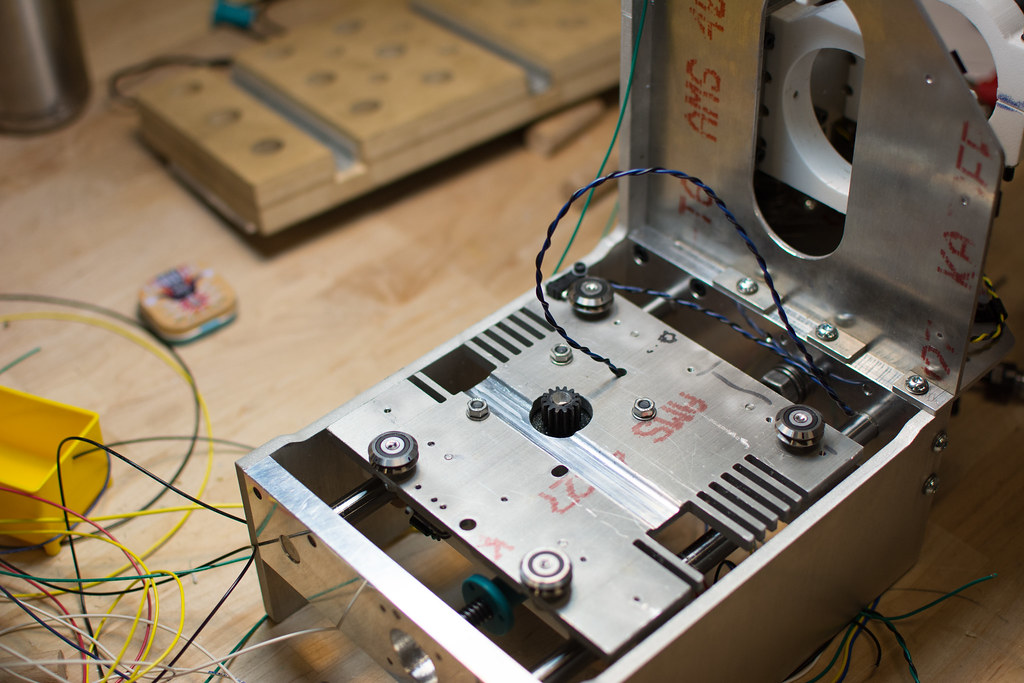

z-axis ways

z-axis ways

Spindle and handwheel

2-part belt drive pulleys for spindle

2-part belt drive pulleys for spindle

old circuit boards

unpacked at the demo

unpacked at the demo

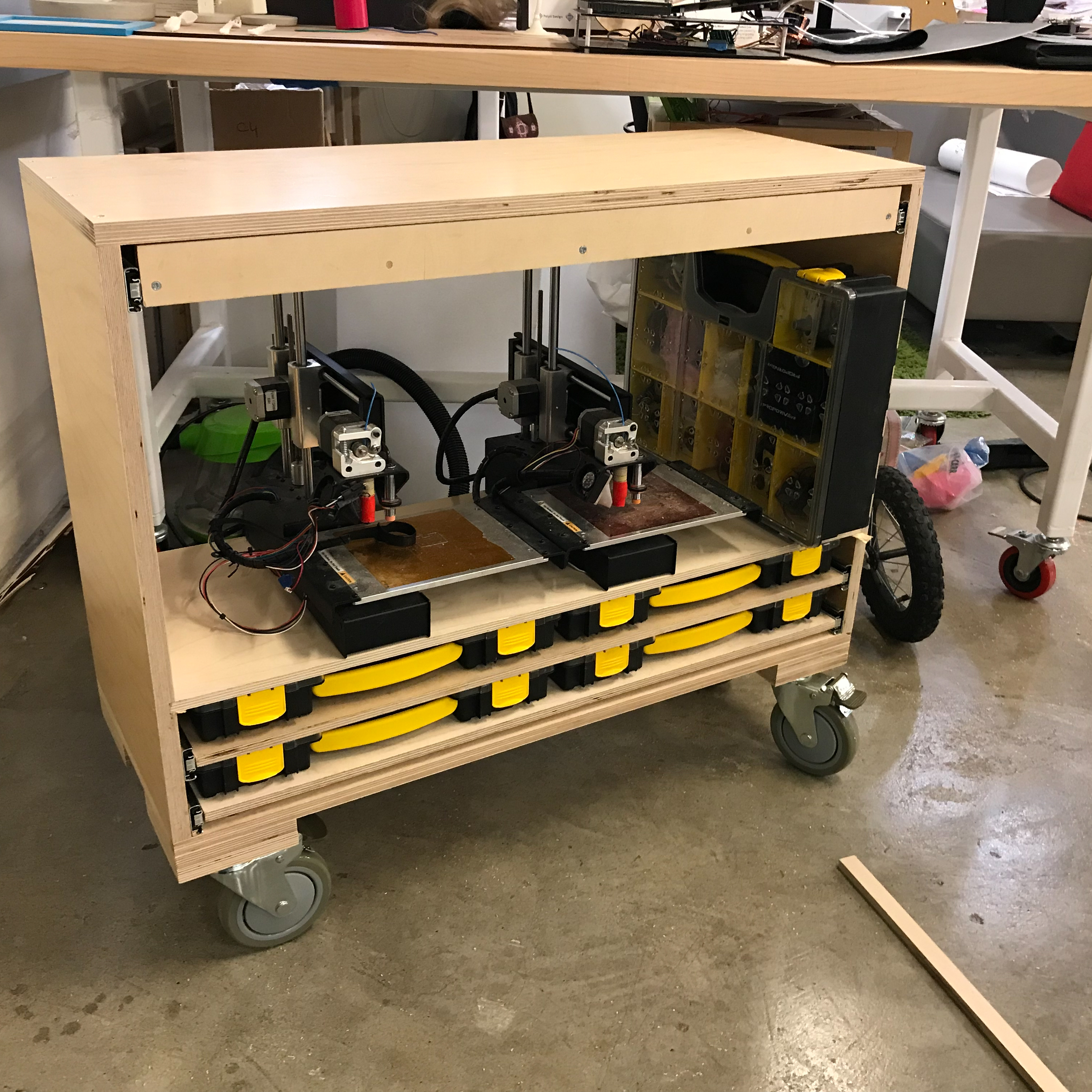

Mobile Shelving Pt. 2

03 Oct 2018

Making some more quick storage before the free wood runs out…

Contains: (1) pullout drawers for component storage, (2) top drawer for metal working tools, and (3) space for 3D printers

After

During

Drawer construction made much easier with undermount mount drawer hardware

Free bin casters and dado routing

No more shears

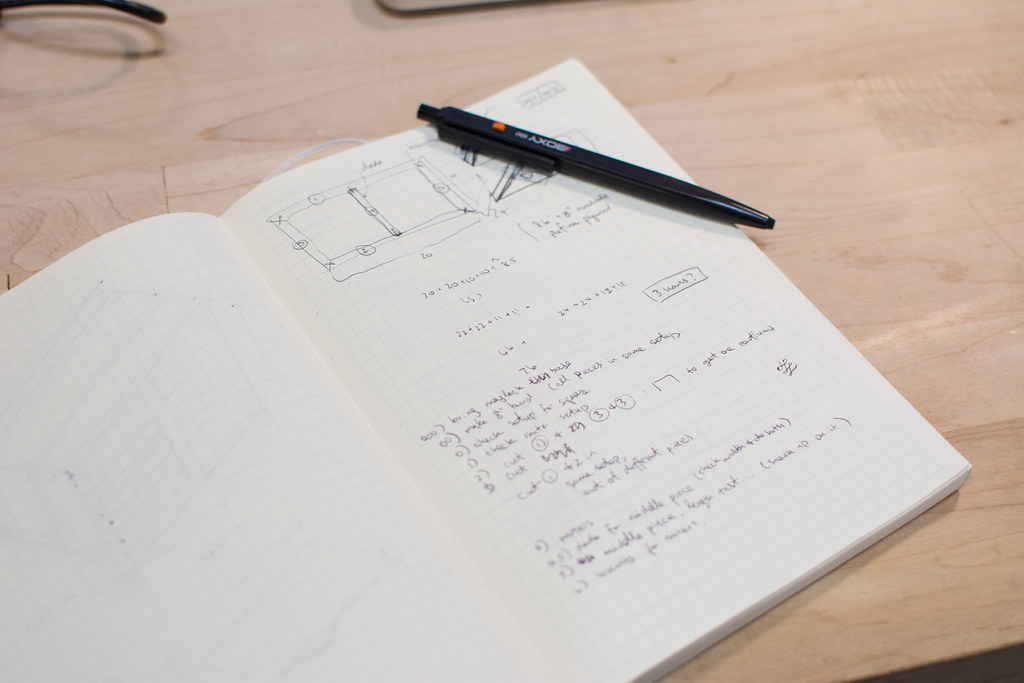

Miters

18 Feb 2018

I recently made a mitered frame to replace a pile of textbooks, using some prefinished plywood scrap.

Rather than making dimensioned drawings in CAD or by hand, I wrote an ordering of table saw setups and cuts that would yield a well fitting box, and the dimensions could be chosen as I worked with the physical material.

Decent miters, courtesy of a digital miter gauge. The face turned out better than the back.

Handplane

01 Feb 2018

Homemade (mostly) wooden hand plane

Many setups, one bed

Many setups, one bed

Alignment holes for glue-up

Alignment holes for glue-up

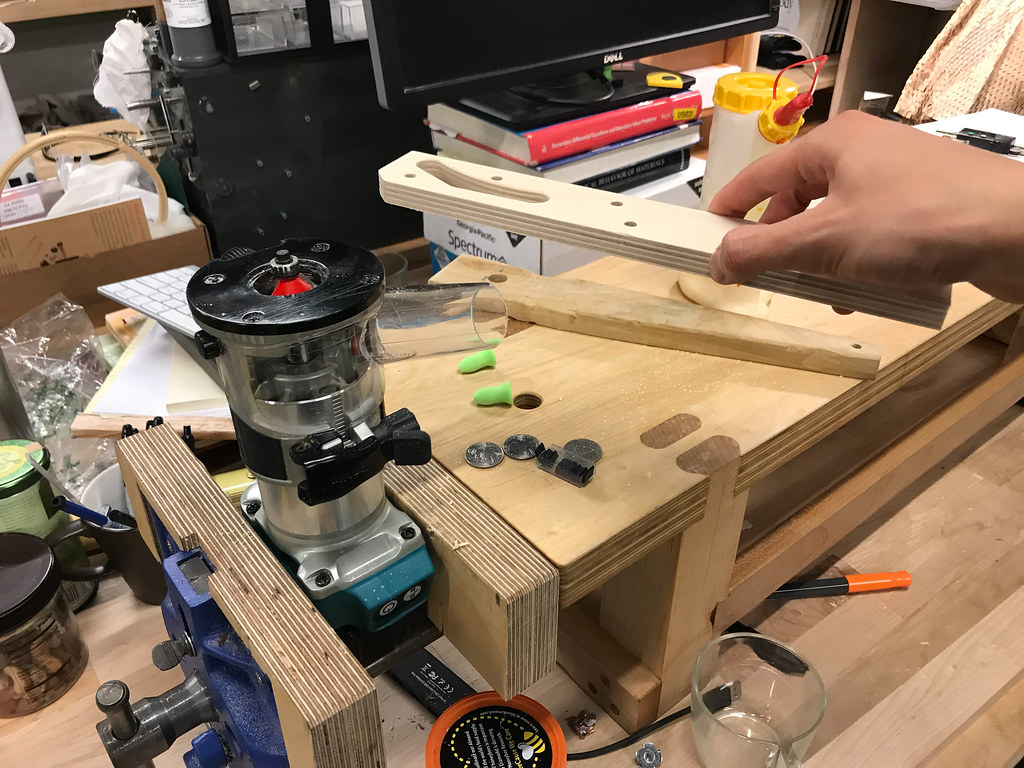

5 second router table, to take some light chamfers

5 second router table, to take some light chamfers

Waterjet steel sole, attached with fixturing tape

Waterjet steel sole, attached with fixturing tape

MKII

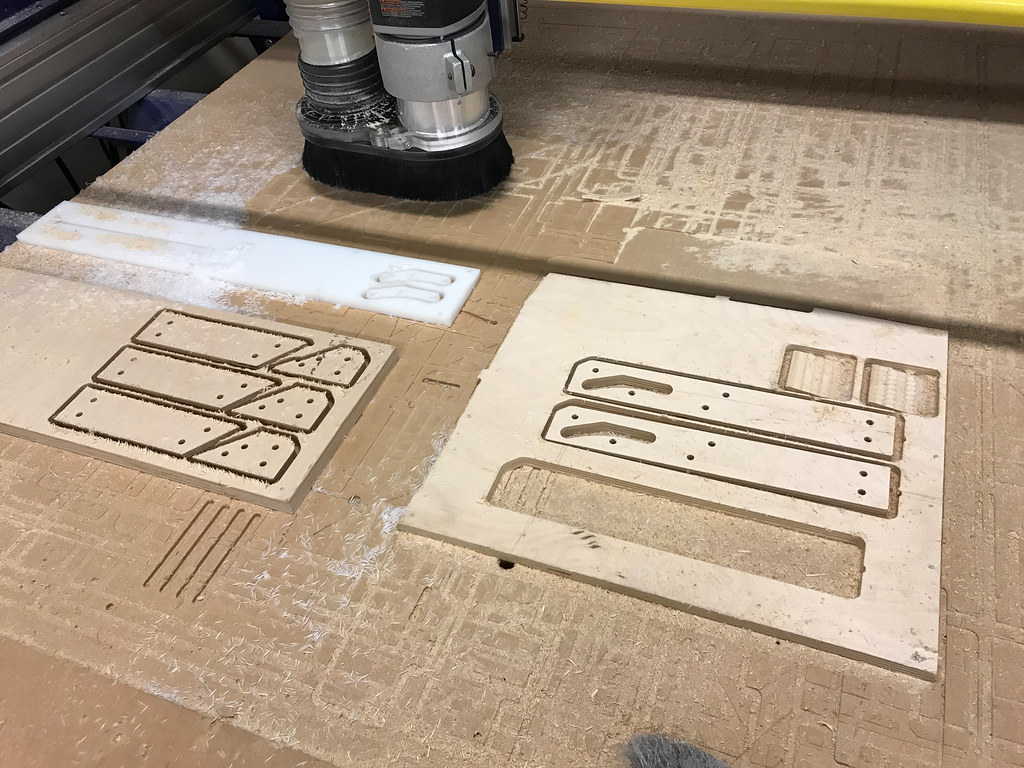

12 Jan 2018

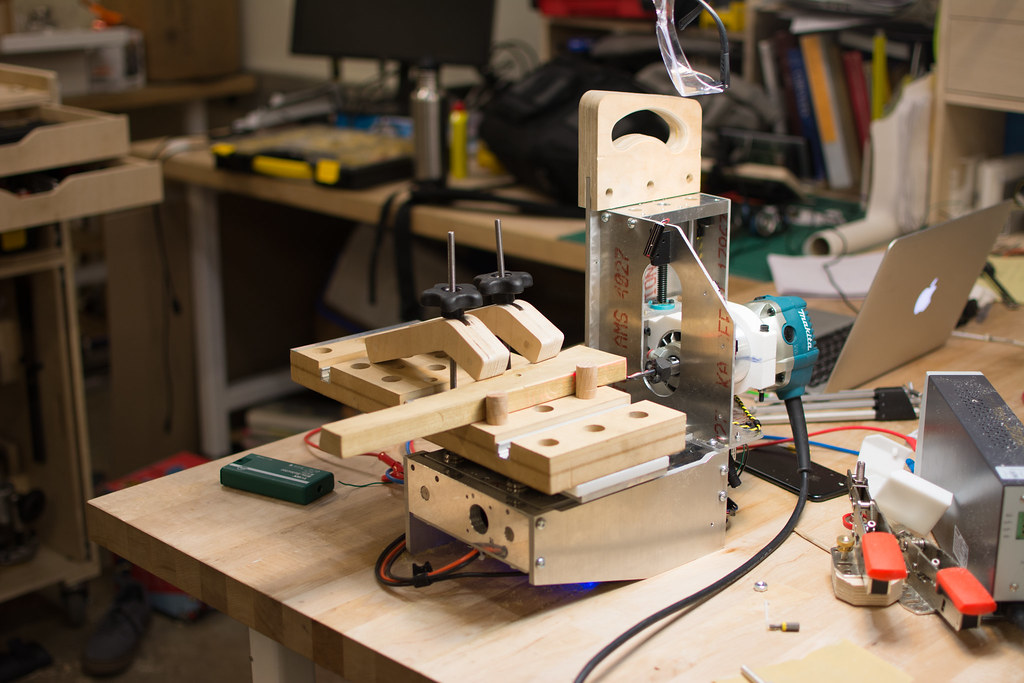

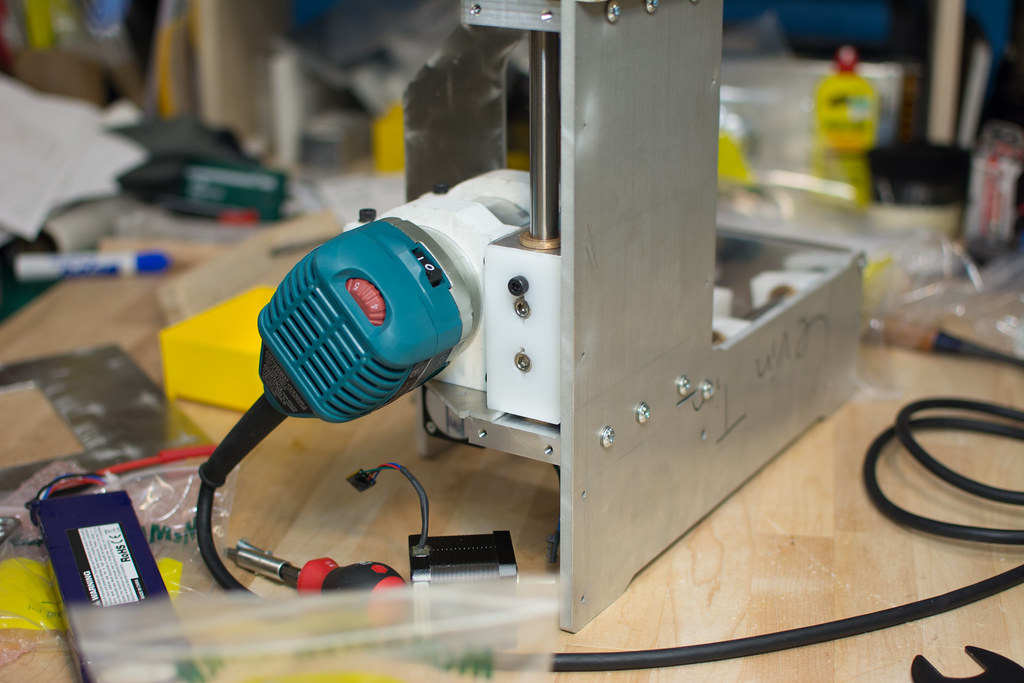

CNC for woodworking. Version 2.

A few pictures taken during the construction and assembly of MatchSticks.

After assembly

Very groovy X axis

End cap for aluminum extrusion Y axis

Plunge axis that couples to the X axis