Shorter projects and experiments

New Website Layout

22 Oct 2017

Redid website with Semantic-UI and Jekyll.

Will still be updating the styles a bit, but most of the content is now up.

Old CSS was messy and difficult to maintain. Now it is better.

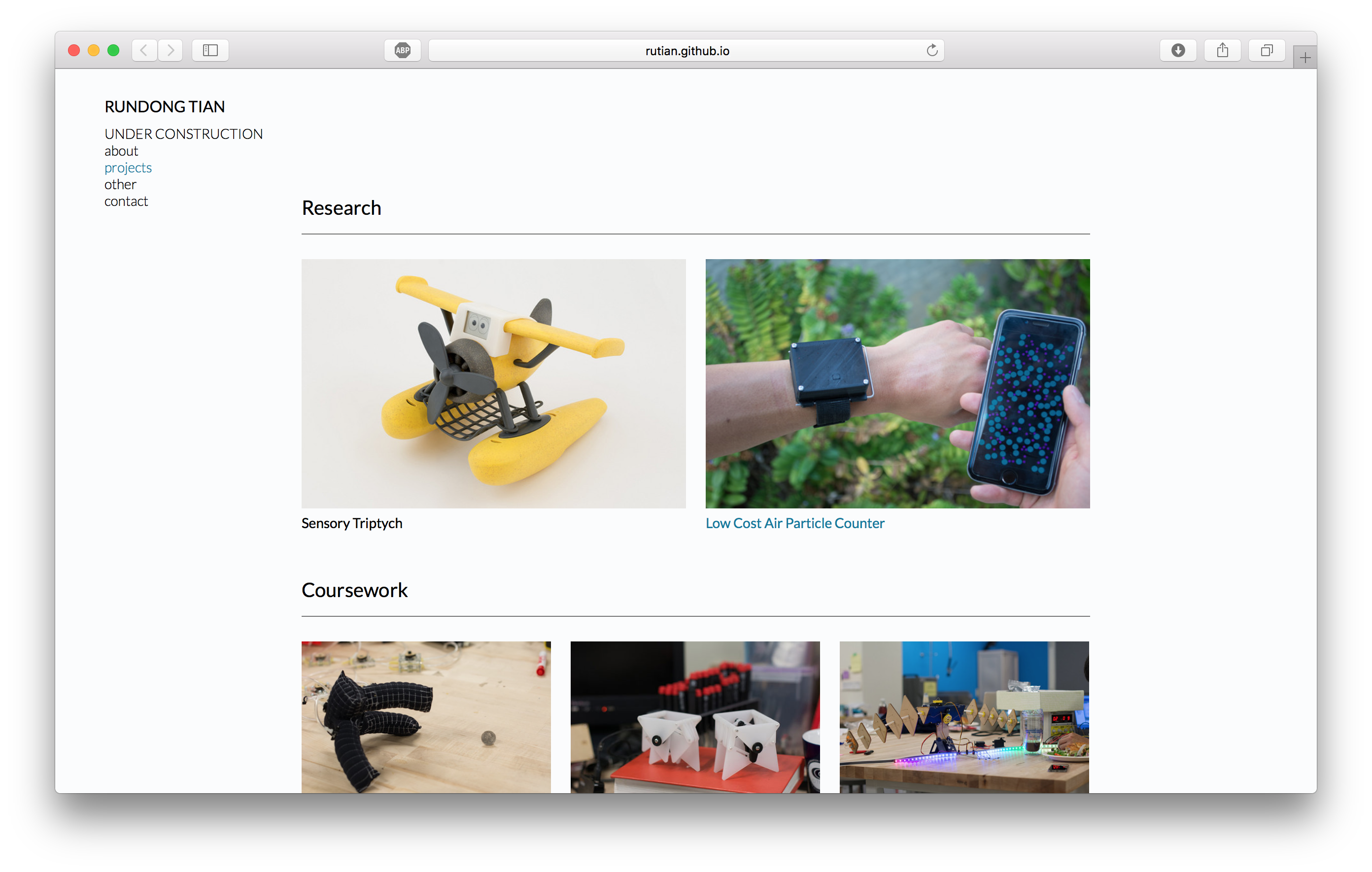

Screenshot of old website with handcoded CSS:

Links for posterity:

Github pages setup for local rendering

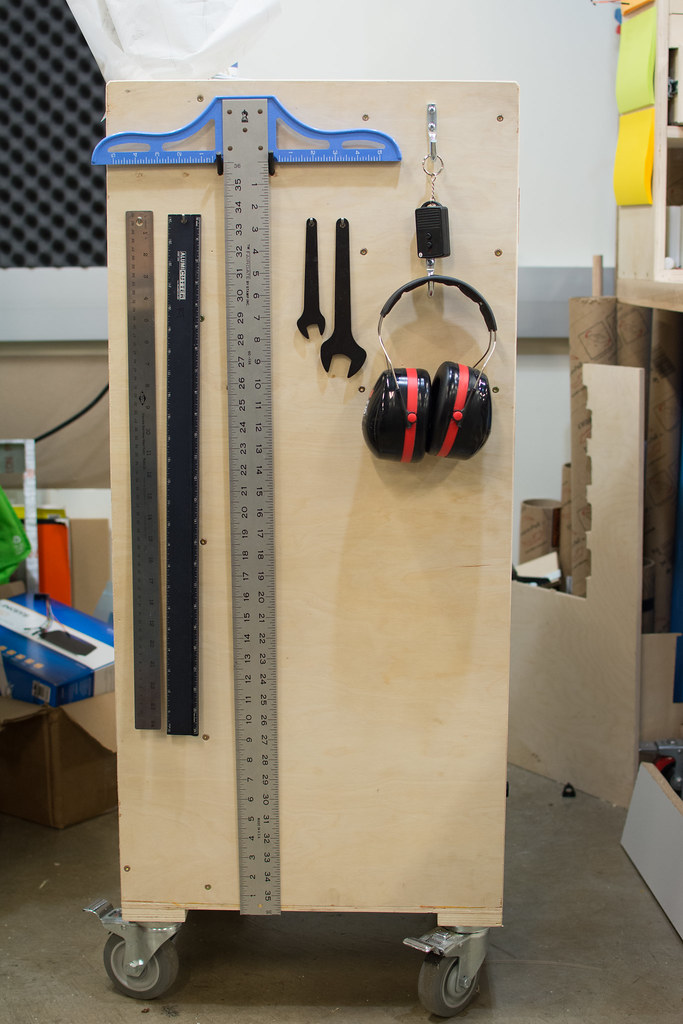

Standing Desk and Tool Storage Update

20 Oct 2017

Left

Left

Front

Front

Right

Right

Back

Back

Woodworking

Woodworking

Box

Box

Some documentation for the build of this cart can be found here.

Small doorstop for keeping the tool chest in place

Small doorstop for keeping the tool chest in place

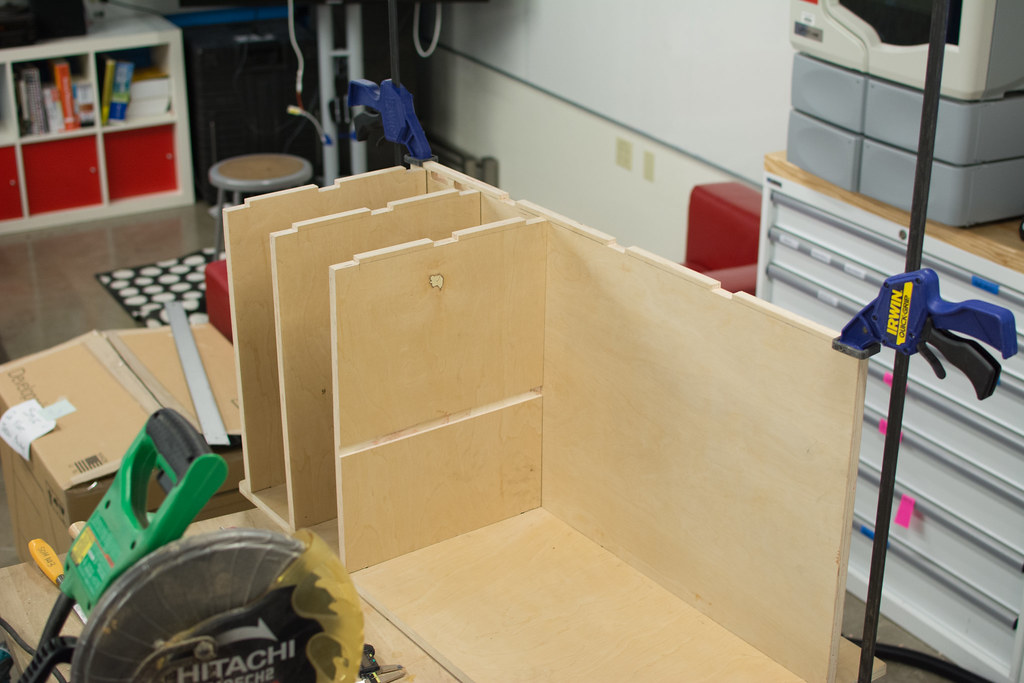

Box with joints

Box with joints

Dry fit after chiseling out rounded inside corners

Dry fit after chiseling out rounded inside corners

Chisel and plane holders.

Chisel and plane holders.

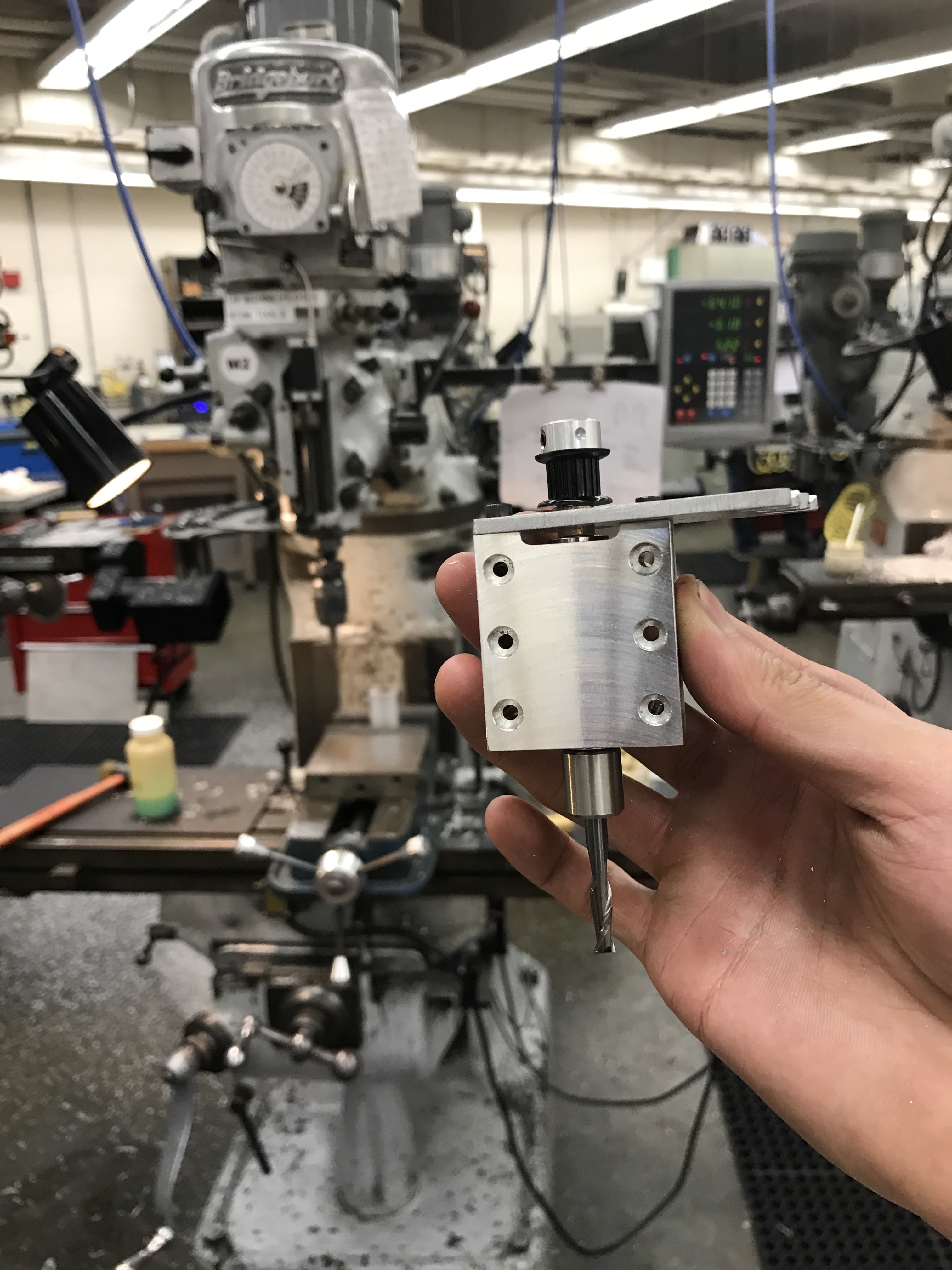

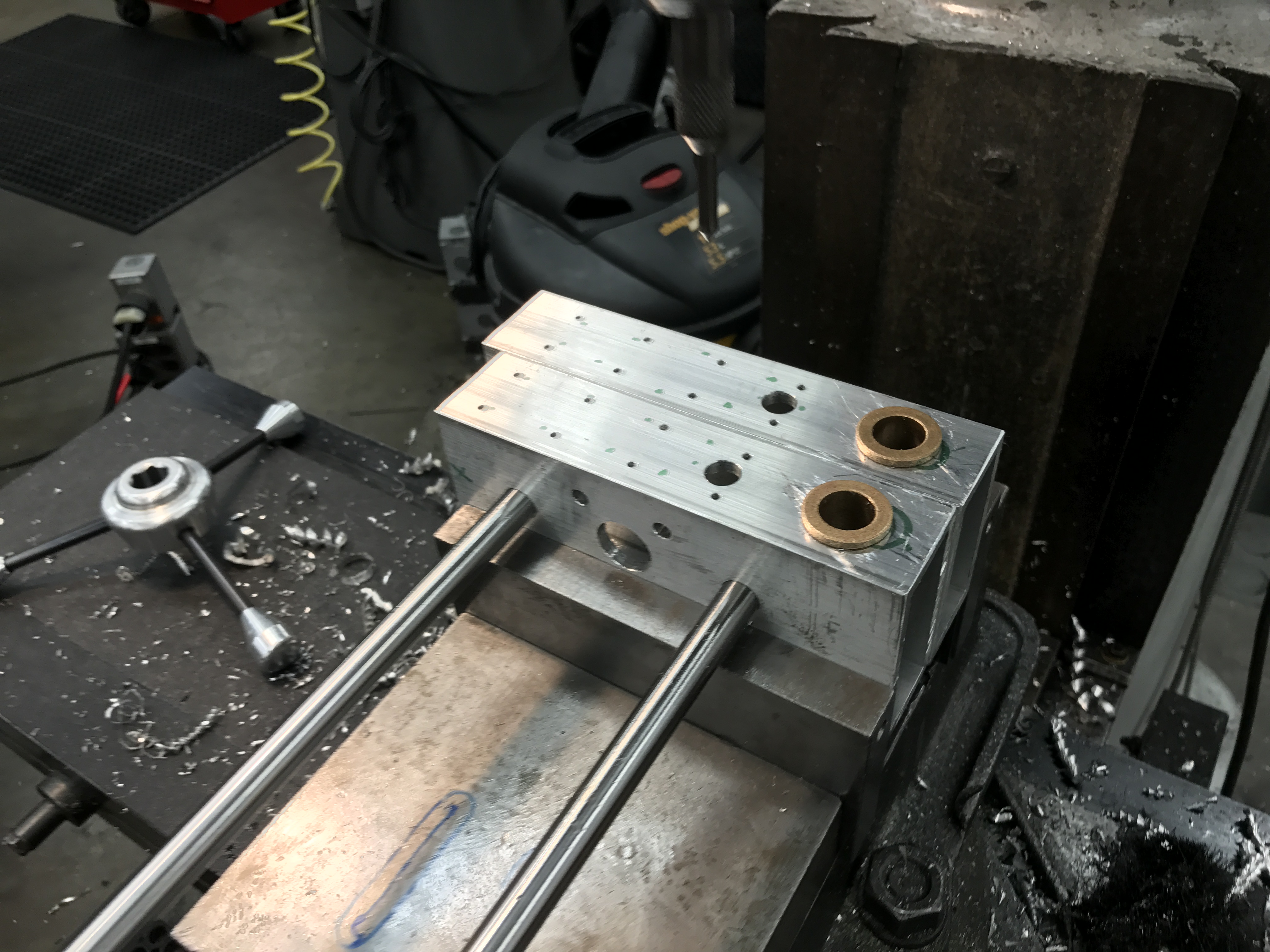

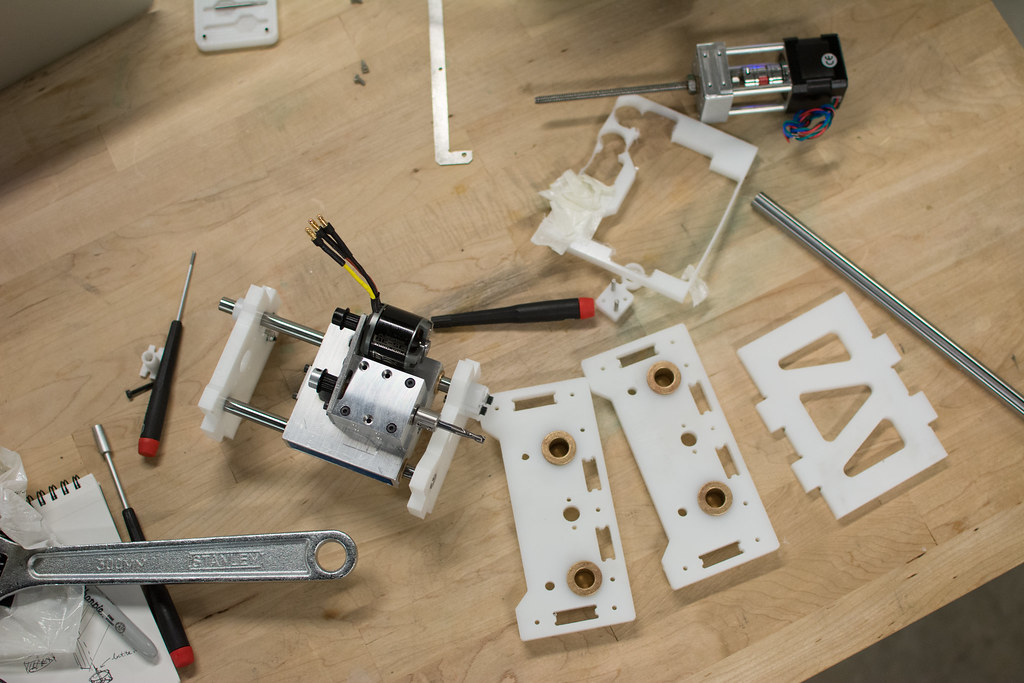

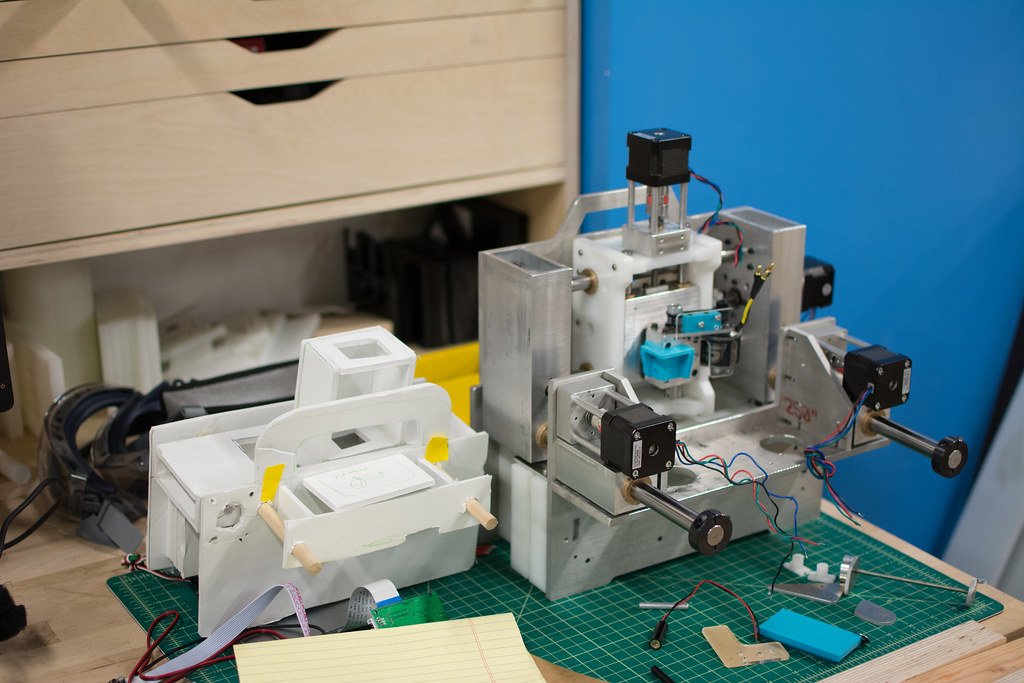

MKI

10 May 2017

CNC for woodworking, version 1.

Mother and child portrait. Based on this.

Mother and child portrait. Based on this.

Match drilled, holes used again for alignment on secondary features.

Match drilled, holes used again for alignment on secondary features.

Assembling the gantry. Two pieces of HDPE where milled in one setup (stacked) to ensure identical center to center distances using a large shopbot.

Assembling the gantry. Two pieces of HDPE where milled in one setup (stacked) to ensure identical center to center distances using a large shopbot.

A little bigger…

A little bigger…

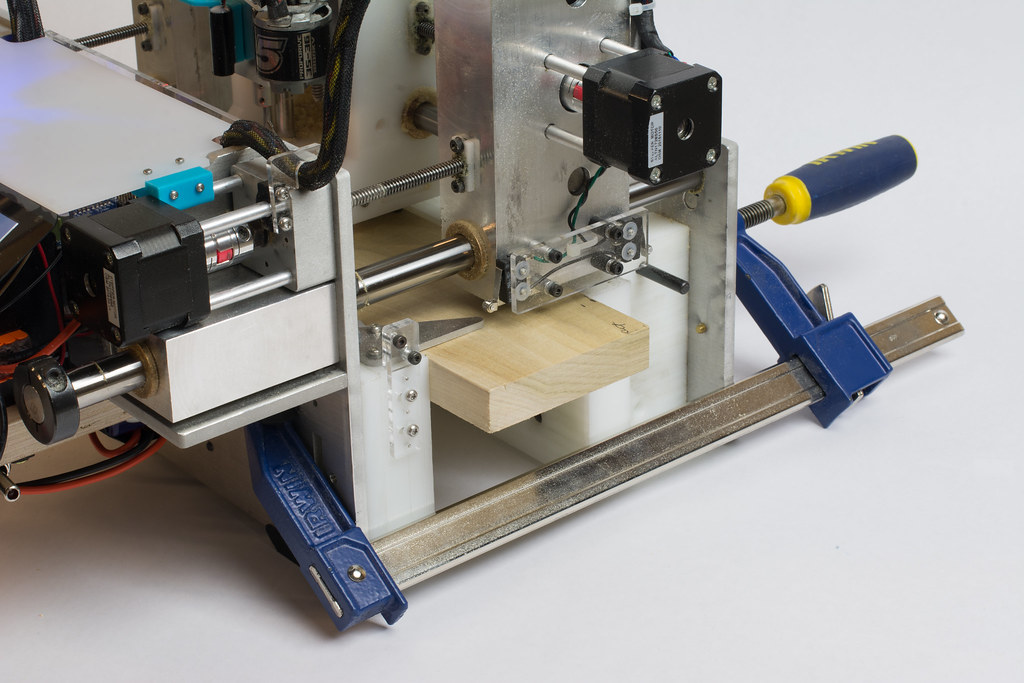

Testing milling in portrait mode.

Testing milling in portrait mode.

Clamping with the ‘fourth’ jaw axis.

Clamping with the ‘fourth’ jaw axis.

Sheet Simulation 2 Ways

10 May 2017

For the CS284B (graphics), my partner and I experimented with various approaches for simulating sheet materials.

All simulations where implemented in Javascript with three.js and a custom math library.

Sheet Model, enable gravity to start. Classic particle based model with strain limiting offering most of the stability. 50x50 node sheet simulated at 60fps.

Simple continuum model, activate by turning on gravity or increasing pressure. Here, I implemented a simple continuum model based on Large steps in cloth simulation. A verlet integrator was used instead of an implicit integrator.

Lastly, I tried to implement a St. Venant-Kirschhoff model with an anisotropic mesh, but was unable to finish debugging it by the end of the semester.

Standing Desk and Tool Storage

13 Jan 2017

Ergo-Shopbotting with the standing desk during construction

Ergo-Shopbotting with the standing desk during construction

Dry fit. No pictures of the glue up, as it was one of the most stressful events of my life

Dry fit. No pictures of the glue up, as it was one of the most stressful events of my life

Casework coming together

Casework coming together

Drawer glue-up

Drawer glue-up

Making tool holders from a failed drawer

Making tool holders from a failed drawer

Holding Tools!